bioplastics vs plastics: what’s better for the environment?

Bioplastics versus Conventional plastics: Environmental Benefits

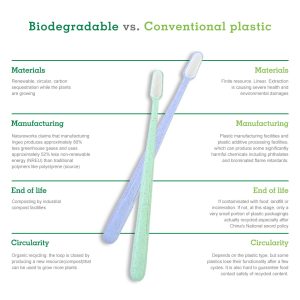

In order to accurately assess the use case for bioplastics, we must understand the environmental profile of the material from resource to end-of-life and whether it fits into a circular economy cradle-to-cradle model.

- Materials: Renewable, circular, carbon sequestration while the plants are growing.

- Manufacturing: Natureworks claims that manufacturing Ingeo produces approximately 80% fewer greenhouse gases and uses approximately 52% less non-renewable energy (NREU) than traditional polymers like polystyrene (source).

- End of life: Composting by industrial compost facilities.

- Circularity: Organic recycling: the loop is closed by producing a new resource (compost) that can be used to grow more plants.

Conventional Plastic

- Materials: Finite resource. Linear. Extraction is causing severe health and environmental damages

- Manufacturing: Plastic manufacturing facilities and plastic additive processing facilities, which can produce some significantly harmful chemicals including phthalates and brominated flame retardants.

- End of life: If contaminated with food: landfill or incineration. If not, at this stage, only a tiny portion of plastic packaging is actually recycled.

- Circularity: Depends on the plastic-type, but some plastics lose their functionality after a few cycles. It is also hard to guarantee food contact safety of recycled content.